- #Grbl controller laser on off serial

- #Grbl controller laser on off driver

- #Grbl controller laser on off full

- #Grbl controller laser on off plus

The controller uses plug in modules for the the ESP32 controller and the stepper motor drivers. It the steppers motors disable, so will the servo and can be moved manually. The feature also uses the $1 (Step idle delay) setting. Therefore it will do a good job of respecting the acceleration and speed settings in the gcode. The servo updates its position 20 times per second. This is very hard on a servo and will overheat and damage it. You will feel the servo continuously vibrating as it pushes against the end point. Make sure you do not adjust the servo so it hits the physical end point of its travel. $132 works the same way for the other end point. %102=90 or $120=110 would be 10% changes in either direction. $102=100 (100%) would be no change to the first end point. We use the Z axis resolution and max travel settings to do this. You can calibrate the end points of the servo to fine tune it. Any values of Z above or below this range would would be limited by the range, so any Z value above 5mm in this example would not move the servo past where it was at 5mm. For example the range could be set for 0-5mm. It then computes and sets a position for the servo.

Each time the servo task runs, it looks at the current position of the Z. Grbl thinks it is running a normal stepper motor on the Z axis. The servo is controlled using a separate RTOS task on the controller.

#Grbl controller laser on off full

You connect to the controller with a web browser and it serves a full featured machine controller to browser. The controller can create its own WiFi access point or connect to an existing WiFi network.

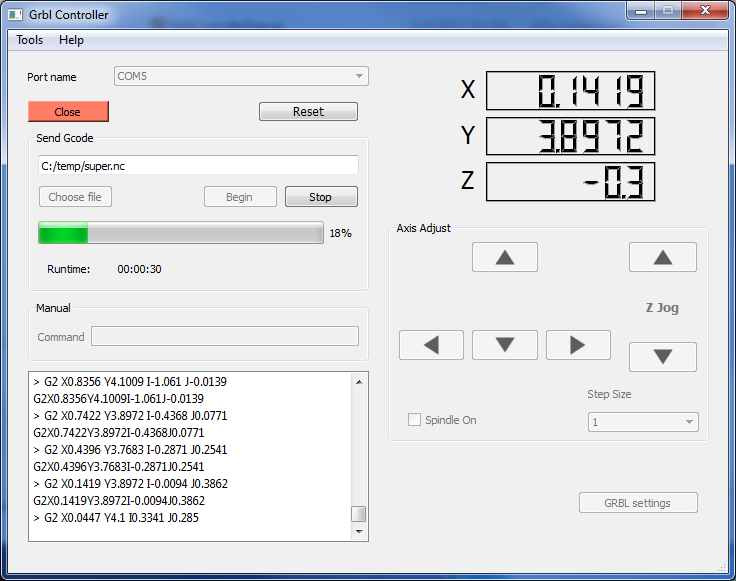

#Grbl controller laser on off serial

This means you can then use existing serial port based gcode senders. When you connect via bluetooth, your phone or computer will create a virtual serial port. This is a great way to use your phone to control a machine. This controller is compatible with virtually all of the serial port gcode senders for Grbl. You can quickly upload files via WiFi or remove it and plug it into your computer. The SD card is a great feature because it is free from connectivity interruptions and you don’t need to stay connected to your machine while it is running the job. There are several ways to connect to the controller, but to run jobs, you basically either stream the gcode or run it from a file on the SD card. It is typically ready to go in a few seconds.

#Grbl controller laser on off plus

#Grbl controller laser on off driver

(2) Stepper Motor Driver Sockets for standard stepper driver modules.Here are the features of the PCB assembly On lasers you need an accurate PWM for laser power control. On pen plotters, the Z axis is controlled by a servo or solenoid. These typically use stepper motors for the X and Y axes. This is a small (70mm x 60mm) PCB with all the features a pen plotter or laser cutter/engraver would need. I have done several pen and laser machines lately, so I decided to create a custom PCB for Grbl_ESP32 for these types of machines.

0 kommentar(er)

0 kommentar(er)